Devices for permanent rope relubrication –

Automatic rope lubricator

Less is more

– Based on this philosophy of continuous lubrication in small amounts, ROTEC GmbH, in collaboration with the lubricant manufacturer ELASKON Sachsen GmbH & Co. KG, developed the automatic rope oiler for cable car ropes. This ensures the rope is continuously maintained, keeping it supple and extending its lifespan.

Automatic rope lubricator

ROTEC GmbH together with the lubricant manufacturer ELASKON Sachsen GmbH & Co. KG developed the automatic rope lubricator for ropeway ropes. This allows the rope to be continuously and precisely lubricated. Additionally, the specially developed lubricant NK-A is used. This helps refute arguments against re-lubrication as well as concerns about damaged roller inserts, dirty stations, slipping clamps, or drive feed issues. Consequently, the rope oiler provides a sustainable solution.

Lubricant NK-A

The lubricant NK-A of ELASKON Sachsen GmbH & Co. KG was specially developed for use in the ropeway sector. It remains clear and penetrates quickly into the interior of the rope. Additionally, it remains intact under pressure between the wires. Compatibility with classic roller inserts has been confirmed through tests. Furthermore, the maintenance of pulling forces on clamps, when NK-A is used correctly, has been demonstrated in tests at the Technical University of Dresden.

Increase the service life

Each revolution of a rope over a sheave causes a displacement and bending of the wires in the rope structure. The smoother a rope is, the gentler this process occurs. However, if a rope is dry or already corroded, the sliding movement of the wires is halted, causing the rope to wear out faster. By re-lubricating, the mobility of the rope is maintained. Additionally, the lifespan can be significantly extended – by years – especially when the rope is continuously maintained. With the automatic rope oiler, it is therefore possible to continuously maintain the rope with small amounts, thereby sustainably improving its lifespan.

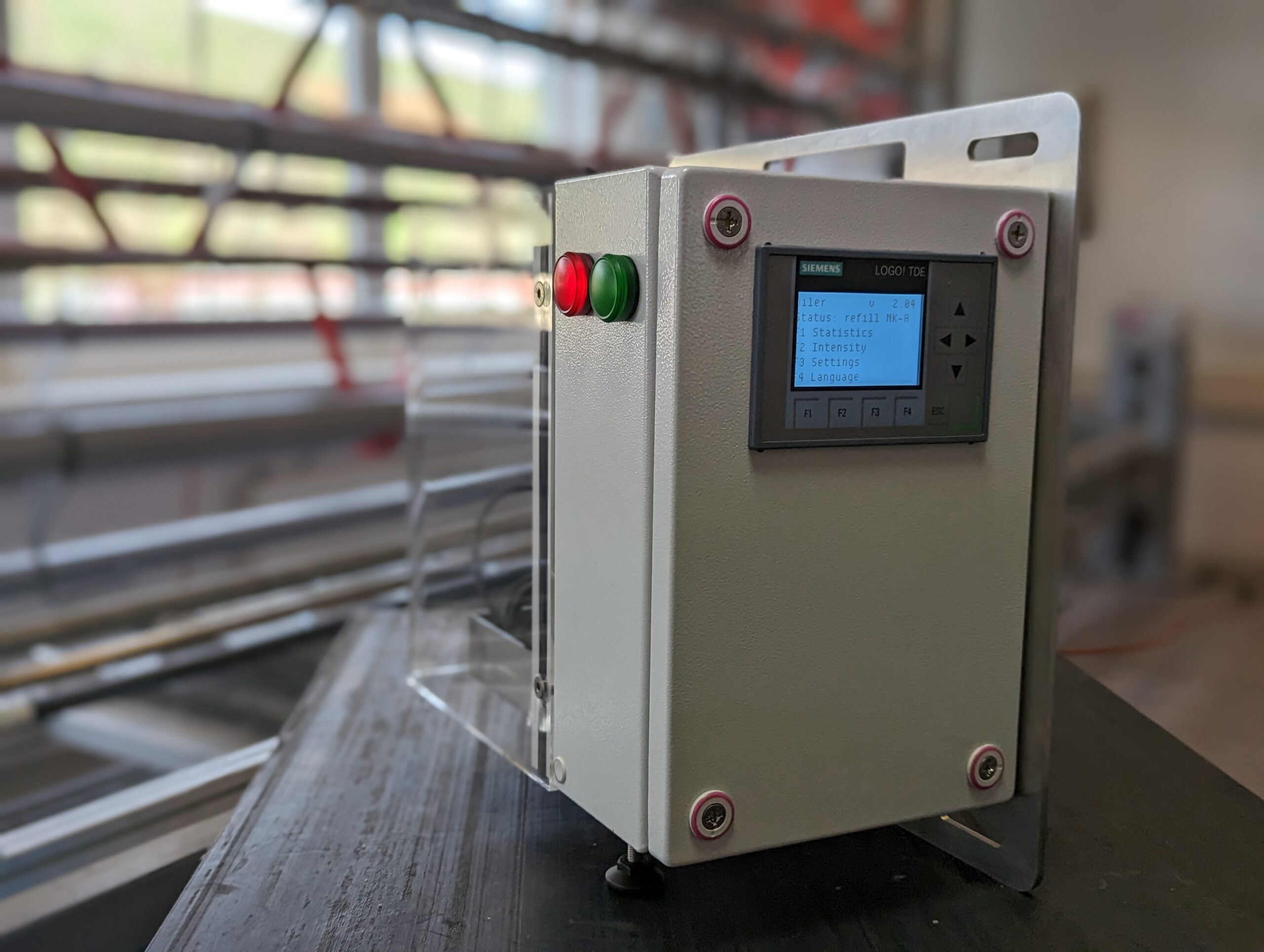

How it works.

Depending on the parameters of rope construction and nominal diameter, rope length, commissioning date, average operating hours per year or season, and average nominal speeds in summer and winter operation, the required amount of oil is calculated individually. Additionally, the rope sensor counts the strand ends and applies defined amounts of oil to the rope through the dosing pump. This ensures that the rope continuously receives a small amount of lubricant without the formation of oil moisture or a significant film on the surface.

Distribution

Die Produktion und der Vertrieb des Geräts zur permanenten Seilnachschmierung erfolgt durch die ELASKON Sachsen GmbH & Co. KG. Nehmen Sie deshalb noch heute Kontakt auf!

Permanent rope relubrication

Are you interested in the topic of permanent rope re-lubrication?

Please contact us without obligation.